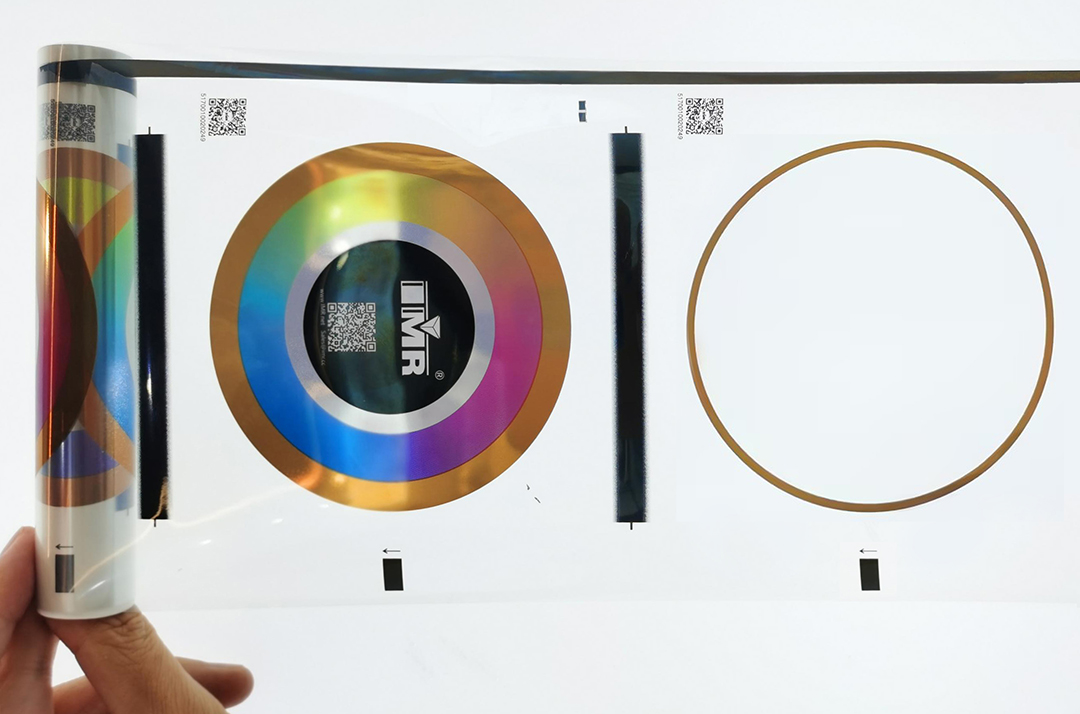

As the core technology of smart surface decoration, IMR (in mold transfer printing technology) is widely used in multiple fields such as home appliances, automobiles, smart homes, smart wearables, OA, etc. So what are the advantages of IMR?

1 Simplified process

No second process, short cycle time; Reduce cost Low failure rate ;

In the production process, there are no follow-up processes, eliminating multiple links in ordinary injection molding, shortening the production cycle of the product. At the same time, due to being fully automatic, it greatly reduces the defect rate of the product, thereby saving production costs.

2 Environment protect

High rate of resource usage;

Due to the use of gravure printing for IMR foil film, the efficient and precision management of gravure printing machines enable precise control of ink production. Prepare a large batch of roll to roll printing in advance, and then place the printed products of the large rolls on the foil feeder. Each injection molding process is carried out with high efficiency and small errors, resulting in good product quality.

No emission;

Compared to traditional injection molding processes, due to the use of fully automatic gravure printing machines, there is no emission of waste (solid, liquid, or gas) for efficient utilization.

Safety;

The entire production process of IMR technology is operated by fully automated equipment, and there will be no harmful gas or liquid emissions during the production process, let alone air or water pollution. In addition, the ink and plastic used in the IMR process comply with environmental standards and can be used in food or medical fields without causing harm to human health or the environment.

3 3Dcomplex pattern

Solid Forming; Art slot; concave convex; Wrinkle

IMR technology can achieve various 3D effects, bumps, textures, etc. on products, providing customers with a different visual and tactile experience.

4 Good surface characters

Hardness; Abrasion resistance; Solvent resistance; Food or Medical industry feasibility;

The products produced by IMR process have high hardness; Wear resistance; Excellent characteristics such as corrosion resistance, and the product can be used in the food or medical industry;

5 Multi Design

The surface of IMR process products can achieve rich and diverse designs, which can meet the personalized appearance needs of today's consumers.

VM&NCVM;

Different color finish( pear, Pulverized, Gradient);

Different pattern (Geometric, wooden, cotton, stone, leather);

Multi finishing(High Glossy, Matt, half-glossy halfmatt);

Multi haptic (soft-tough, baby skin, hair-line)

Please feel free to consult us!